Use case Loccioni

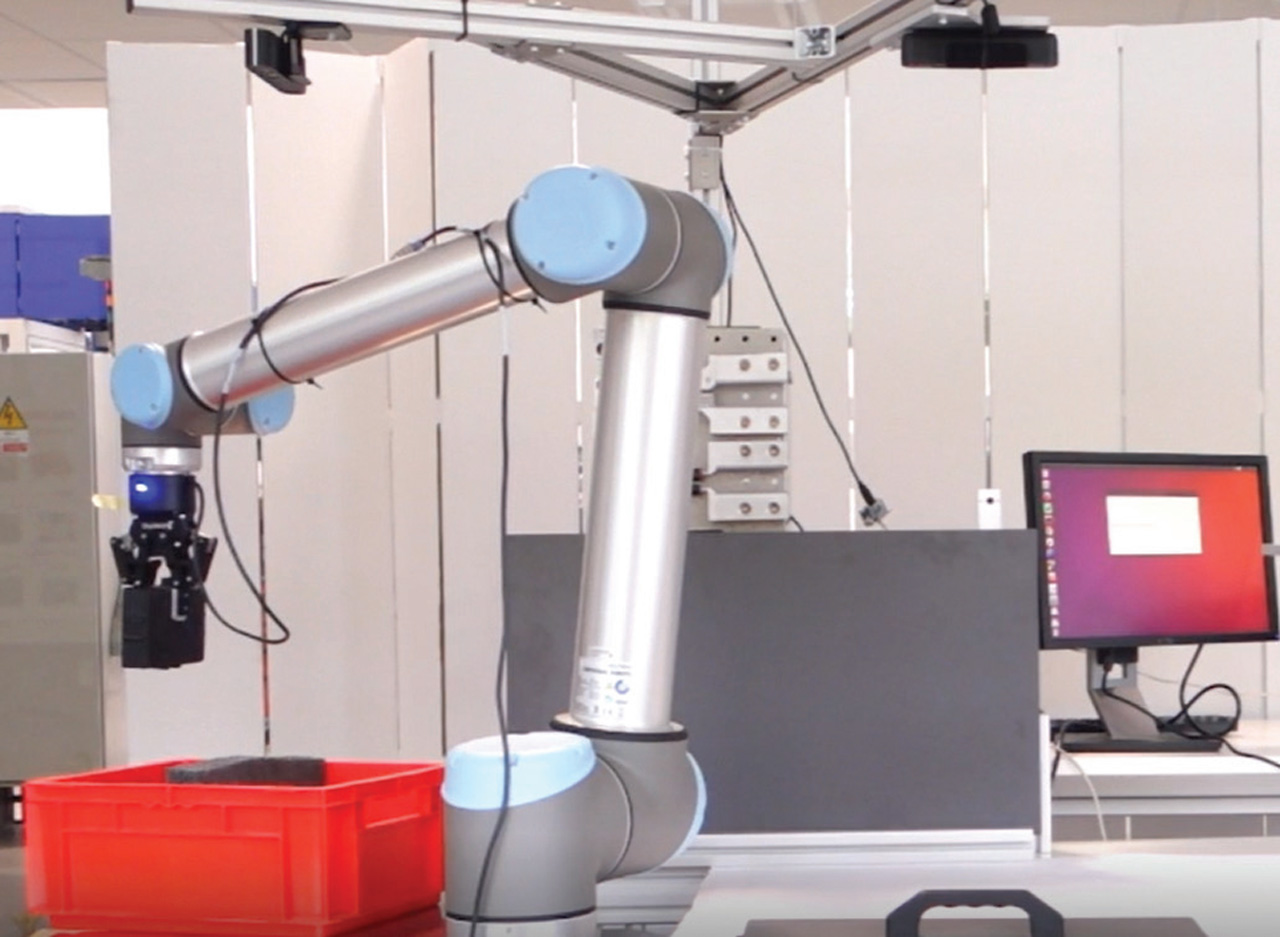

ADVANCED MANIPULATION OF OBJECTS IN THE PRODUCTION LINE

Manipulation of different objects done automatically by a robot without a priori information is one of the challenges of recent years. To date, a robot to manipulate objects must have a lot of a priori information, such as its size, its position, the material it is made of, etc.

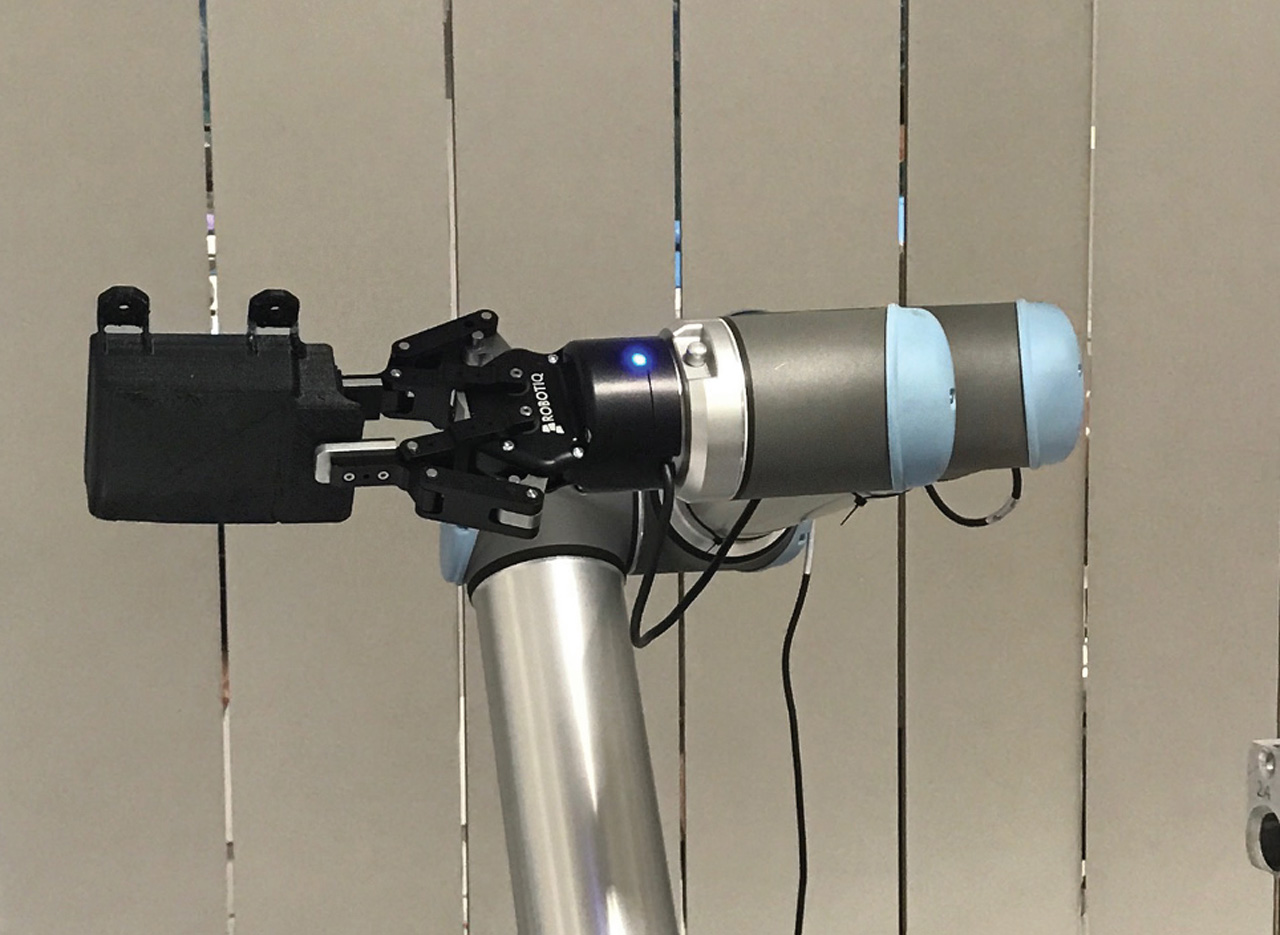

The objective of the project and the prototype developed was to verify the feasibility of the use of convolutional neural networks called Quality Grasp - Convolutional Neural Networks (GQ-CNN) that through the 3D image of the object provides the coordinates of the best grip for the robot.

The application chosen was the manipulation of control units in the automotive sector that must be taken from a box where they are placed at the end of the line to be placed in another box for shipment to the final customer. The application is suitable for testing the functionality of the GQ-CNN as there are many types of ECUs and updating the robot program that needs to be done for manipulation is quite burdensome as it requires the work of skilled personnel.

In particular, new algorithms have been studied and innovative sensors used in combination with robots in order to give the robot those cognitive characteristics that will be necessary in order to adapt to a flexible and non-repetitive production. The complexity of the algorithms is still high and the project has therefore given the opportunity to better understand the potential of Artificial Intelligence, its needs in terms of hardware required to make it work and especially the skills needed to know how to use it.